NC State researchers are turning wood byproducts into sensory hydrogels that can react to different stimuli and, through advanced manufacturing methods, are made into sustainable, biodegradable smart materials that can be used in agriculture, health care and even veterinary medicine.

“The future is more sustainable, and nanotechnology, nanomaterials and biomaterials, those are part of that future,” said Lokendra Pal, an associate professor of forest biomaterials in the College of Natural Resources.

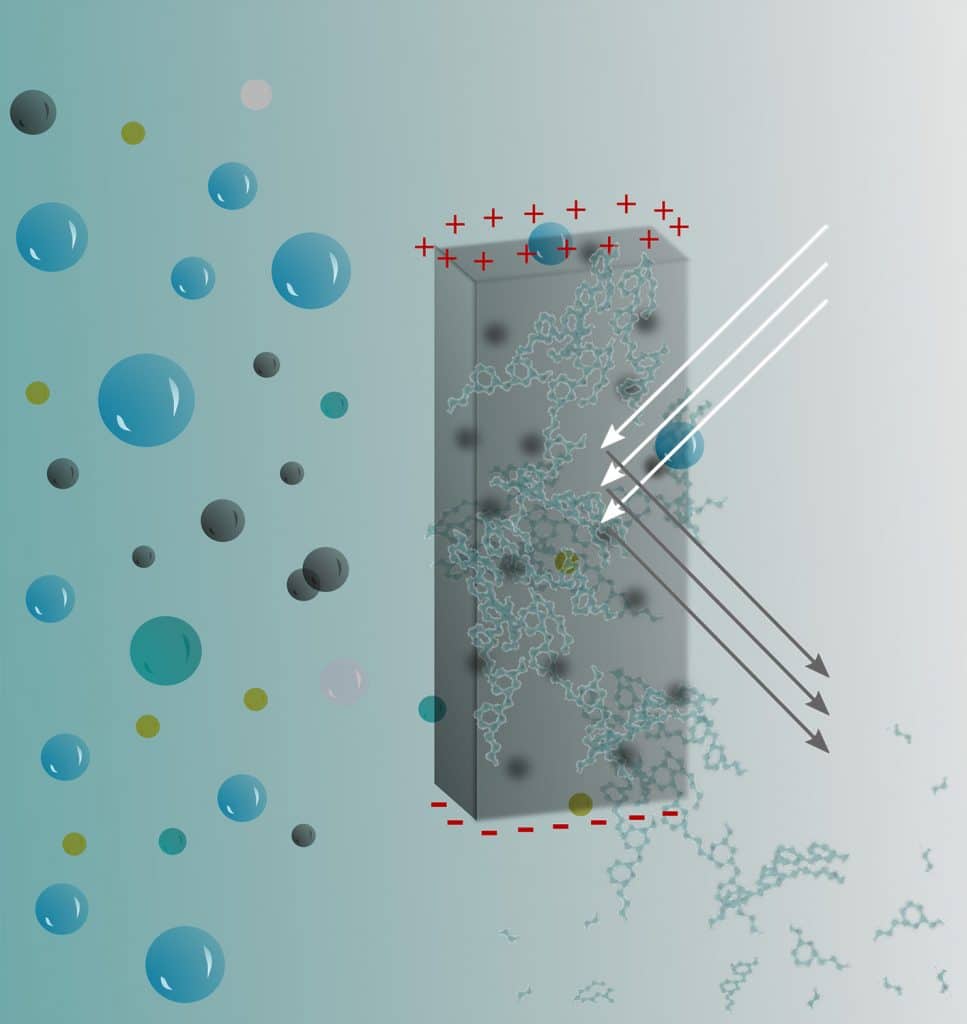

Hydrogels are porous, polymeric materials that are up to 90% water. Because they’re water-heavy, they’re permeable on a molecular level, which means they can be altered by chemical and mechanical modifications to change physically and chemically when met with certain stimuli, like temperature, pressure and moisture. These changes can be monitored by electrical or mechanical transducers or simply by sight.

Researchers in the Department of Forest Biomaterials have turned carboxymethylcellulose and cellulose nanomaterials, which are abundantly available from trees and agriculture residues, into biodegradable hydrogels by using advanced manufacturing. The innovation is a sustainable solution to an array of big problems. Take, for example, food insecurity, which is influenced by pests, plant disease and climate change.

“We’re looking at green agriculture,” Pal said. “Some plants respond to different wavelengths of light, so the material can be used in greenhouses or other amenable places. Wavelengths can be directed so the plants can grow faster. Agriculture, especially in the most populated regions of the world, will suffer from undue stresses on the plants induced by climate change. These materials can provide a microenvironment to deal with it.”

And as the world’s population ages, there is an increasing need for assisted care, diagnostic tools and sensory devices. The material can even be used in contact lenses, meeting eyes’ friction, oxygen and comfort requirements.

“We can tune the materials’ properties, like oxygen transmission rate, and they can be customized for people’s needs and manufactured on demand using a 3D printer,” Pal said. “There’s no one-size-fits-all.”

The hydrogels are so customizable that Pal and his colleagues are exploring creating a similar lens for animals. While participating in the National Science Foundation’s Innovation Corps program, they realized animals recovering from eye injuries or surgeries could benefit from a sensory gel-type bandage.

“Humans can tell you whether they’re having issues with their eyes,” Pal said. “Because these hydrogels have a sensing mechanism, a trigger can cause it to change color or have another reaction. Animals can’t talk to you, but with these, you can see what’s going on.”

The goal now is to collaborate with NC State’s College of Veterinary Medicine for further research and testing. While that process is ongoing, it could be a year until the team brings sensory hydrogels for agriculture to the market, studying crop protection and organic farming. That process, too, is highly collaborative, just as the College of Natural Resources is.

“If you look at our college, one of our biggest strengths is our different departments,” Pal said. “Forestry can genetically and biotechnologically design and plant seeds for faster growing and disease -free trees and forests. Our department takes those and works through more green chemical processing and advanced manufacturing to transform them into various bioproducts, biochemicals and bioenergy. Parks, Recreation and Tourism Management looks at all of the human aspects. Together we can start to grow trees through sustainable forest management and create future bio-based materials that benefit society as well as the environment as a whole.”

- Categories: