What if you could help slow down climate change by replacing your standard, plastic Halloween mask with an alternative that’s not only renewable but also biodegradable? Researchers at NC State’s College of Natural Resources have been working for more than two years to make this a reality across the United States.

“We spend billions of dollars on masks and other single-use plastic items that the majority of us use for a few minutes or hours,” said Lokendra Pal, an associate professor in the Department of Forest Biomaterials. “We want to make a small, positive impact by making a mask that is nature-derived and cost effective but doesn’t pollute the environment.”

The most expensive part of Halloween is the costume. Each year, 67% of Americans spend approximately $3.2 billion on costumes alone.

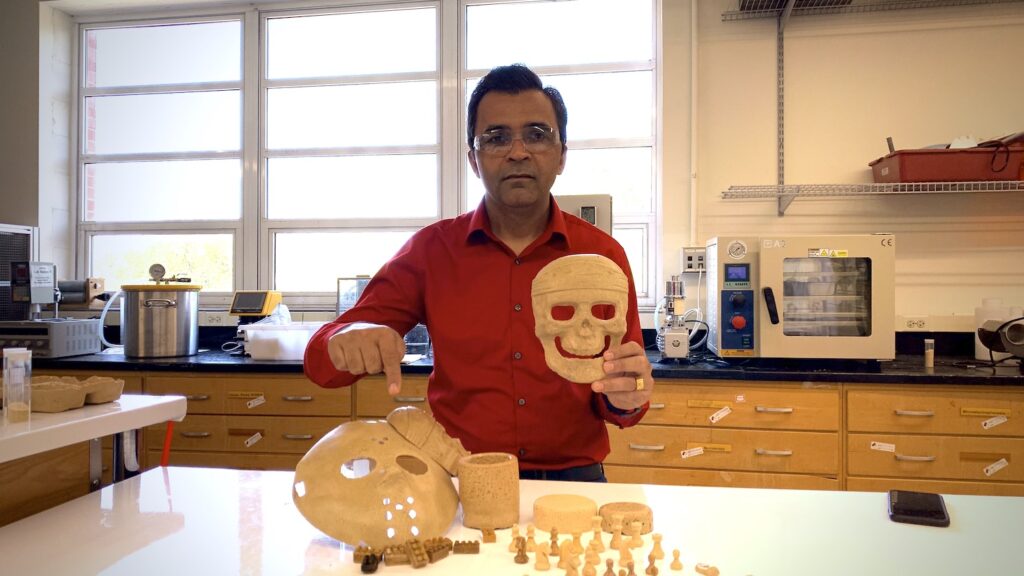

Pal and his team of researchers are using biomass residues such as sawdust, wood residuals and agricultural waste, along with cellulose-based binding materials, to create more sustainable, inexpensive masks for Halloween.

Eliminating plastic waste

Single-use plastic items like Halloween masks are the leading worldwide cause of pollution and are accelerating climate change. Although recycling can reduce waste, more than 90% of all plastic ends up in the environment or landfills.

“Landfills are at an all-time high in the United States, with a cumulative production of 7.8 billion pounds of plastic produced since 1950,” Pal said. “There’s not enough space to send the waste that we’re generating today.

Currently, over 2 billion tons of solid waste is produced annually worldwide. About 150 million tons of that waste is derived from single-used plastic items — the equivalent to the weight of about half of the human population’s biomass worldwide.

From the landfill, single-use plastic items travel through the wastewater system into the ocean. It can take up to 500 years for plastic items to biodegrade in the ocean.

Since plastic items such as styrofoam are lightweight and brittle, they break down into small pieces that animals can digest. This not only impacts the health of sea creatures but also humans, because plastic items can absorb metals and other harmful materials from the Earth’s crust.

“We are making something from renewable resources that could last for a few minutes, hours or days and then be recycled, biodegraded or composted,” Pal said. “If left alone, it can biodegrade in the environment quickly.”

Creating sustainable masks

To make the masks, approximately 75-90% of the material used is a wood byproduct — in this case, sawdust. More than 65 million tons of wood waste is generated each year, including 25 million tons of non-recyclable wood waste. In addition, approximately 39 million dry tons of mill and urban wood residues are being unused each year in the U.S.

To bind the sawdust, Pal and his colleagues use cellulose-based materials. These materials are refined to the right size and can be solvent casted, molded or 3D printed. A dye can also be added to the mixture to create different colors for the masks, along with coatings to change the surface of the mask to make it more glossy and to enhance its water resistance. Other customizable features include size, pigment and texture.

Several companies are interested in commercializing this technology, and researchers like Pal are looking to move the masks up to a large scale where prototypes can be created. With help from potential partners, production can start with lumber companies supplying the sawdust and chemical companies producing the bio-based binding material. Testing could then begin on a product scale before the masks are sold to the general public. A patent is currently pending for the technology.

In addition to Halloween masks, Pal and his team are looking to use this sustainable process to replace other single-use plastic items like food containers and packaging materials. Globally, the packaging industry accounts for approximately 42% of plastic waste, a number that is multiplying with people placing a lot more orders online amid the COVID-19 pandemic.

“Their orders come in big packages with a lot of polystyrene — a plastic derived from petroleum — to fill the empty space and provide the cushioning,” Pal said. “In this case, our technology has the potential to replace those polystyrene materials. Packages filled with bio-based peanuts will help make the e-commerce industry more sustainable.”

- Categories: