Bleaching Technical Services

The Go-To Place for Solutions to Bleaching Challenges

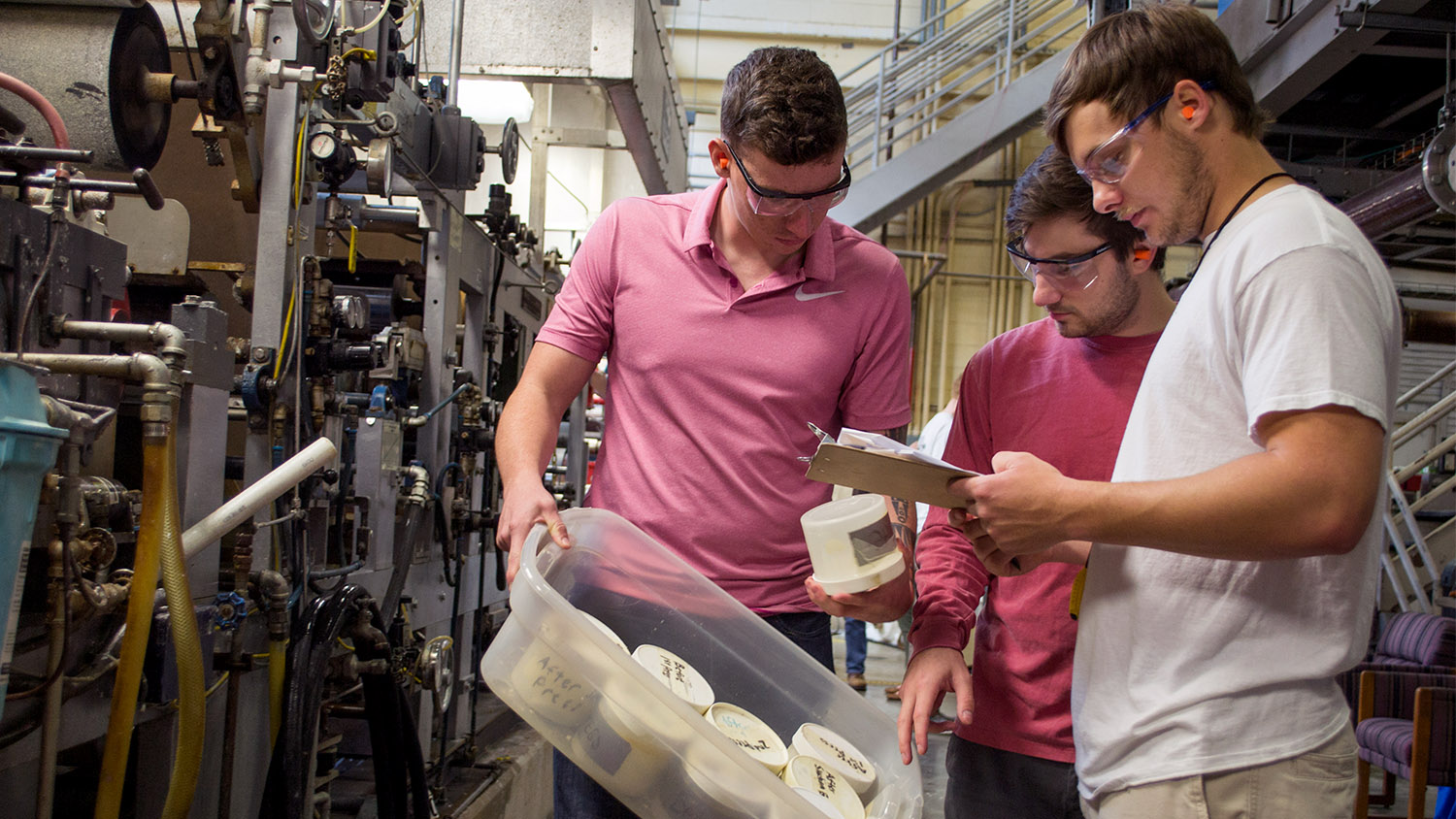

The mission of the Pulp and Paper Technical Services program is to support our allied industries with high quality, cost-effective services. From small-scale laboratory testing to pilot-scale production of large quantities of pulp or paper from a variety of sources, we are well-equipped for almost any technical challenge related to pulping and pride ourselves on a total customer focus.

Bleaching

NC State has a wealth of experience in the bleaching of fibrous furnishes, with experience extending to both ECF and TCF sequences and including low-, medium- and high-consistency conditions. Screening and preliminary trials may be conducted cost-effectively in sealed plastic bags (atmospheric) or small bombs (pressurized). Larger quantities may be bleached using equipment in the pilot plant.

Our bleaching agents experience includes: chlorine, hypo, chlorine dioxide, oxygen- and peroxide-reinforced extraction, oxygen, peroxide, ozone, peracids, enzymes and mediated enzyme systems.

Bench-Scale

NC State 0.8-gallon (3-liter) Pressure Bombs for Cooking or Bleaching

Number available: 6

Construction: 316 SS

Capacity: 200 grams dry chips, 200 grams medium- to high-consistency pulp

Features:

- each bomb has its own top-mounted valve for introduction of gases

- each bomb has its own thermocouple for monitoring of temperature

- rotating rack in hot-air oven permits six bombs to be processed at the same time (insures good mixing of chemicals and raw material)

- two bombs coated with Teflon for maximum brightness development

Process options:

- digestion

- oxygen bleaching (high and medium consistency)

- oxygen- and peroxide-reinforced extraction

- pressurized peroxide

Paprican-Designed 3-gallon (11.4 liter) Batch Digester with Internal Moving Fingers

This reactor is well-suited for medium- or high-consistency bleaching of pulp with a variety of agents, including oxygen. The reactor is also an excellent bench-scale digester for non-wood materials. The fingers provide a lifting and turning action similar to a screw-type digester.

Capacity: 1.1 OD lb (500 OD grams) of medium- or high-consistency pulp; 250-400 AD grams of bulky non-wood material

Construction: 316 SS lined with Teflon

Features:

- 150 psig max. pressure

- can be pressurized with oxygen or other gases

- internal fingers lift and mix material; variable speed

- external electrical heating bands

7.5-gallon (28-liter) Direct-Steamed Rotary Batch Digester/Reactor

This vessel can be used for cooking or bleaching at a medium or high consistency.

Capacity: 15 dry pounds chips or 5-6 dry pounds bulky nonwood materials

Construction: 316 SS

Features:

- 250 psig max pressure

- rotating action insures good mixing of chemicals and raw material

- heating via direct steam injection

- can be pressurized with oxygen or other gases

Quantum Mini-Mixer

This equipment is perfect for bleaching small batches of pulp at a medium consistency, especially when fluidization or intense mixing is required.

Capacity: 350 ml bowl = 30-50 g OD pulp at medium consistency

Construction: 316 SS

Features:

- top-mounted impeller provides mixing or fluidization at variable speeds and intervals bowl can be pressurized with gases up to 125 psig heated block provides temperature control (110 C max.) chemical injection port permits chemicals to be injected during the process

Quantum Mixer

This equipment is a proven workhorse for bench-scale bleaching, especially when intense mixing, gas-liquid mixing or fluidization is required.

Quantity available: 2

Capacity: 1 gallon (3.8 liters), 1.1 lb OD 500 g OD) pulp at medium consistency

Construction: 316 SS

Features:

- bottom-mounted impeller provides mixing or fluidization at variable speeds and intervals

- bowl can be pressurized with gases up to 125 psig

- heating bands provides temperature control

- chemical injection port permits chemicals to be injected during the process

Pilot-Scale

200-gallon (760-liter) and 2500-gallon (9462-liter) Agitated Stock Tanks for Low-Consistency Bleaching

When bleaching large quantities of pulp economically at an atmospheric and low-consistency, large tank-based bleaching is an attractive option. Each of our 2,500-gallon tanks can hold 600-1000 OD pounds (272-454 OD kg) of pulp at a consistency of 3-5 percent. Heating is provided by direct steam injection via a pick heater and agitation may be provided on a continuous or intermittent basis. Smaller, 200-gallon tanks are also available for smaller batch sizes.

Black Clawson 200-gallon (760-liter) Hydrapulper

This equipment is very flexible and can be used both for stock-prep pulping, mild chemical pulping, and low- or medium-consistency bleaching. The ability to inject steam and/or chemicals is particularly attractive.

Capacity: 200 gallons (760-liters), can hold up to

45-90 OD lb (21-40 OD kg) of pulp at a consistency of 3-6 % (Vokes rotor) or up to 150 OD lb (68 OD kg) of pulp at medium consistency (helical rotor)

Construction: epoxy-lined carbon steel

Features:

- Vokes rotor for low-consistency pulping

- Hi-con helical rotor for high-consistency pulping and bleaching

- 20-HP motor with variable-speed drive

- can be pressurized up to 50 psig due to bolted-head construction

- steam, gases (oxygen, ozone), and/or chemicals can be injected into vortex zone

845-gallon (3200-liter) Rotary Globe Batch Digester/Reactor

This vessel is invaluable for the production of pilot quantities of pulp and can be used for digestion of both wood and nonwoods in addition to all types of bleaching at medium and high consistencies.

Capacity: 500 dry pounds of wood chips or 200-400 dry pounds of bulky non-wood materials

Construction: carbon steel with 316 SS internal cladding

Features:

- 15 rpm rotation speed insures good mixing of chemicals and raw material

- heating via direct-steam injection through axial joint

- can be pressurized with oxygen or other gases