Fiber Recycling Technical Services

The Go-To Place for Solutions to Fiber Recycling Challenges

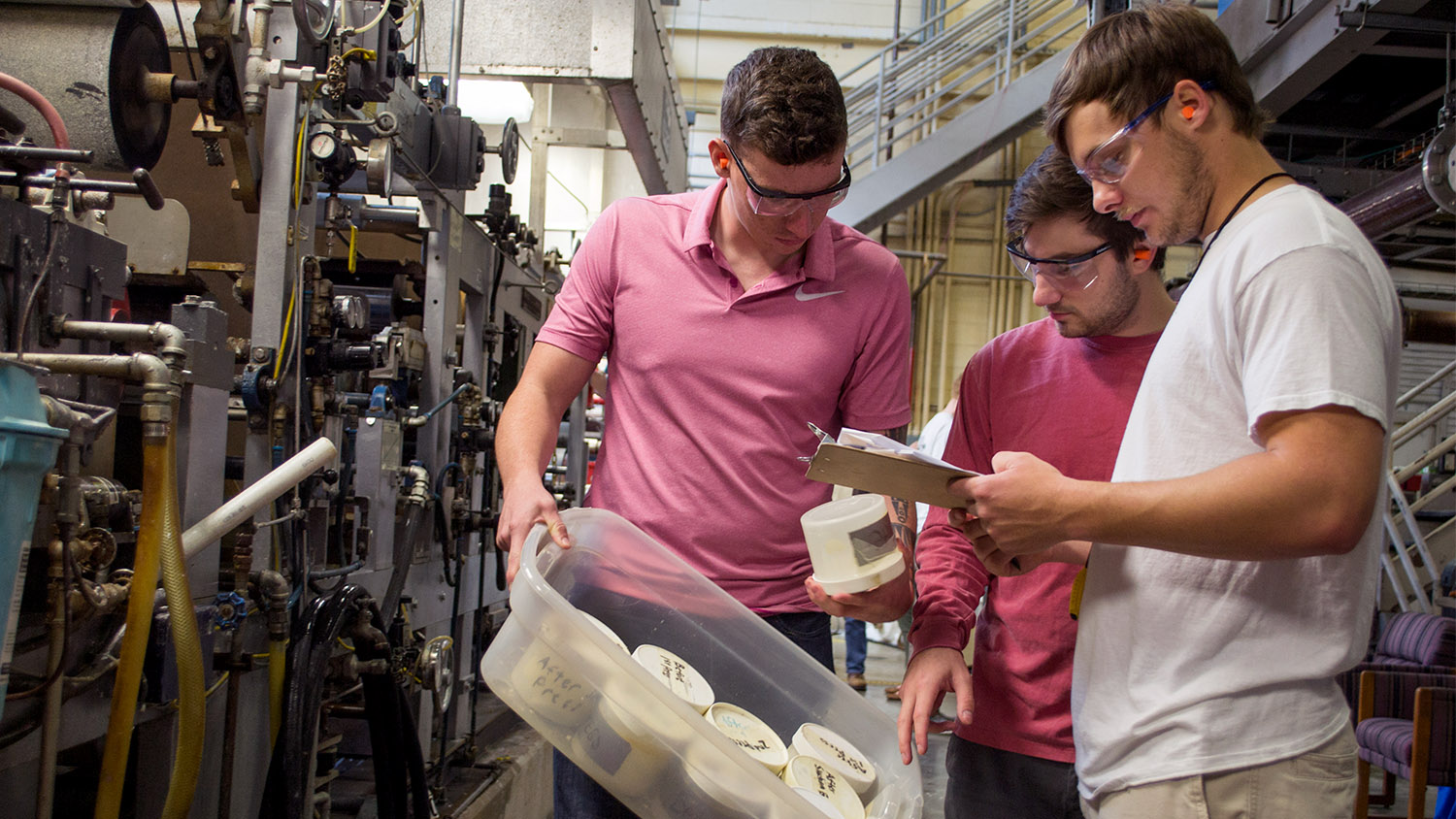

The mission of the Pulp and Paper Technical Services program is to support our allied industries with high quality, cost-effective services. From small-scale laboratory testing to pilot-scale production of large quantities of pulp or paper from a variety of sources, we are well-equipped for almost any technical challenge related to pulping and pride ourselves on a total customer focus.

Fiber Recycling

NC State has achieved an outstanding reputation in the industry for technical services and research in the area of fiber recycling, including stickies identification and removal; repulpability and recyclability of barrier-treated (e.g. waxed) and other difficult materials; and enzymatic and agglomeration de-inking. Whatever the challenge, we have an assortment of equipment to treat small samples at bench scale or large samples at pilot scale.

Bench-Scale

Adirondack 1-gallon (3.8-liter) Low-Consistency Benchtop Pulper

Capacity: 1 gallon (3.8 liters), up to 0.3 OD lb (135 OD g) of pulp at 4 % consistency

Construction: 316 SS

Features:

- variable-speed drive

- jacketed hot-water temperature control system

Adirondack 2-gallon (7.6-liter) High-Consistency Benchtop Pulper

Capacity: 2 gallons (7.6 liters), up to 2 OD lb (0.9 OD kg) pulp at 15% consistency

Construction: 316 SS

Features:

- variable-speed drive

- jacketed hot-water temperature control system

3-gallon (11.4-liter) Benchtop Low-Consistency Pulper

Capacity: 3 gallons (11.4 liters), up to 1.2 lb OD (0.6 kg OD) pulp at 6 % consistency

Construction: 316 SS

Features:

- side-mounted Vokes rotor

Voith Laboratory Flat Screen

Number available: 3

Available with the following slot sizes:

- 0.006″

- 0.008″

- 0.010″

- 0.012″

Pulmac Master Screen

This equipment is invaluable for any bench-scale screening when dynamic shear is desired. We have a variety of slot sizes available to meet various needs.

Modular Centrifugal Cleaner System

This unique and very useful system permits the analysis of centrifugal cleaning operations under realistic conditions, but requires only a small amount of fiber (4-6 OD pounds.) Cleaners are mounted above a 200-gallon (750-liter) tank from which they are fed and into which accepts and rejects are discharged. Multiple trial conditions may be used for a single batch of pulp.

A high-speed, high-head centrifugal pump permits the development of the head and flow levels required for typical cleaners and fluid-filled, large-faced pressure gauges permit accurate measurement and control of pressure drop.

Cleaners available for isolated or series runs:

- Beloit Posiflow

- Beloit Uniflow

- Celleco low-density

- Noss forward canister

- Noss reverse canister

Customer-supplied cleaner bodies are easily installed in the system and a variety of nozzle types and inserts are available for each cleaner.

Wemco Atmospheric Flotation Cell

Number available: 2

Capacity: 0.7 gallons (2.5 liters), 0.03-0.06 OD lb (14-28 OD g) at 0.5 – 1% consistency

Features:

- air injection at point of agitation

- variable air flow rate and agitator speed

Shinhama Laboratory Kneader

This equipment is useful for ink dispersion, fiber surface modification, and strength enhancement. This particular device features twin eccentric shafts, which provide an intense rubbing action to pulp. Intensity is varied both by the number of passes and by an adjustable restrictor pin on the discharge.

Construction: 316 SS

Pilot-Scale

Black Clawson 200-gallon (760-liter) Hydrapulper

This very flexible piece of equipment can be used both for stock-prep. pulping, mild chemical pulping, and low- or medium-consistency bleaching. The ability to inject steam and/or chemicals is particularly attractive.

Capacity: 200 gallons (760-liters), can hold up to 45-90 OD lb (21-40 OD kg) of pulp at a consistency of 3-6 percent (Vokes rotor) or up to 150 OD lb (68 OD kg) of pulp at medium consistency (helical rotor)

Construction: epoxy-lined carbon steel

Features:

- Vokes rotor for low-consistency pulping

- Hi-con helical rotor for high-consistency pulping and bleaching

- 20-HP motor with variable-speed drive

- can be pressurized up to 50 psig due to bolted-head construction

- steam, gases (oxygen, ozone), and/or chemicals can be injected into vortex zone

50-gallon (190-liter) Pilot Pulper

Capacity: 50 gallons (190 liters), up to 17 OD pounds (7.7 OD kg) of pulp at 5 % consistency or 42 OD pounds 19 OD kg) at 12 percent consistency

Construction: 316 SS

Features:

- 10-HP motor

- low-consistency (Vokes) and high-consistency (helical) rotors available

- atmospheric de-inking capability with Lamort-style passive air intake shroud

Ahlstrom M200 Centrisorter Centrifugal Pressure Screen

This unit has been modified to accept a 100 gpm (380-lpm) feed rate.

Features:

- 50-HP motor, 1200 rpm

- foil-type (LR) rotor

Baskets available:

- Slots: 0.010″ (0.25 mm)

- Holes: 0.063″ (1.6 mm) or 0.008″ (0.20 mm)

Gauld Periflow 140 Centrifugal Pressure Screen

Features:

- 60-HP motor with variable-speed drive

- taper-shear rotor

- internal accepts (rotor) shower and rejects nozzle flush

- Baskets available:

- Slots: 0.008″ (0.20 mm) or 0.016″ (0.41 mm)

- Holes: 0.032″ (0.81 mm); 0.062″ (1.6 mm) or 0.082″ (2.1 mm)

Equipment for Centrifugal Cleaning

- Single bodies of the following centrifugal cleaners are available for flow-through production of cleaned pulp:

- Beloit Posiflow This is a forward cleaner with a feed rate of about 70 gpm. A variety of nozzle types are available for optimum cleaning efficiency.

- Beloit Uniflow This is a reverse cleaner with a feed rate of about 100 gpm. A variety of reject nozzles and inserts are available.

- Celleco Low-Density cleaner This is a heavyweight contaminant cleaner with a feed rate of about 100 gpm.

- Noss Horizontal Canister Cleaner (Forward and Reverse) This canister cleaner may be run with either forward, reverse, or forward/reverse modes.

Beloit Pressurized Deinking Module

This unit is designed for flow-through deinking under air-pressurized conditions.

Features:

- Feed rate is designed at 70 gpm (265 lpm).

- Air flow rate and system pressure may be adjusted.

- May be operated in single-pass or circulation mode.

Voith Atmospheric Flotation Cell

This pilot unit is designed for flow-through atmospheric deinking.

Features:

- Feed rate is 150 gpm (570 lpm).

- Air is inducted passively at the stock infeed point and mixed with the stock. Foam overflows one side of the unit via a weir, while the deinked stock flows out the other end.

- May be operated in single-pass or circulation mode

Bauer Hydrasieve Slanting Screen

This equipment is designed to take low-consistency stock and thicken it passively to 3-6 percent.

Construction: 316 SS

Face: 24″

Screen: 0.010 slotted wave plate

Renneberg Pilot Screw Press

This equipment is useful for intense dewatering of pulp slurries. Discharge consistencies of up to 40 percent are possible, depending on the furnish.

Construction: 316 SS

Features:

- 10-HP motor with variable-speed drive

- 3 feet (1 m) long, 6″ (15-cm) diameter

Filtration Engineers Pilot Rotary Drum Filter Washer

This equipment may be used either for dewatering or intense washing.

Features:

- 3 feet (1 m) diameter, 1 foot (0.3 m) face width

- separate vacuum headers for vat and mat sections

- 316 SS wetted parts

- up to three wash showers available with variable flow

- rider rolls available for increased dewatering

- vat agitator

- discharge consistency 8-15 %

- capacity 30 gpm (114 lpm)

Sunds CD-300 Mechanical Pulping Pilot Plant

Capacity: up to 3 tons/day continuous feed on wood chips

Features:

- two true, real-time stages of refining

- atmospheric pre-steaming

- 3:1 volumetric reducing screw for plug feed into reactor

- impregnator box for impregnation with chemicals

- 40-gallon (150-liter) pre-heating vessel with nuclear level control and up to 30 minutes retention, 150 psig max.

- primary refiner: 300-HP, 3600 rpm

Pressurized cyclone permits primary and secondary stages to be run at different pressures secondary refiner: 250-HP, 3600 rpm interstage reactor permits treatment of primary-stage pulp with aqueous or gaseous agents prior to secondary refining, 150 psig max. Dedicated process computer with energy consumption monitoring