Paper Making and Testing Technical Services

The Go-To Place for Solutions to Papermaking and Testing Challenges

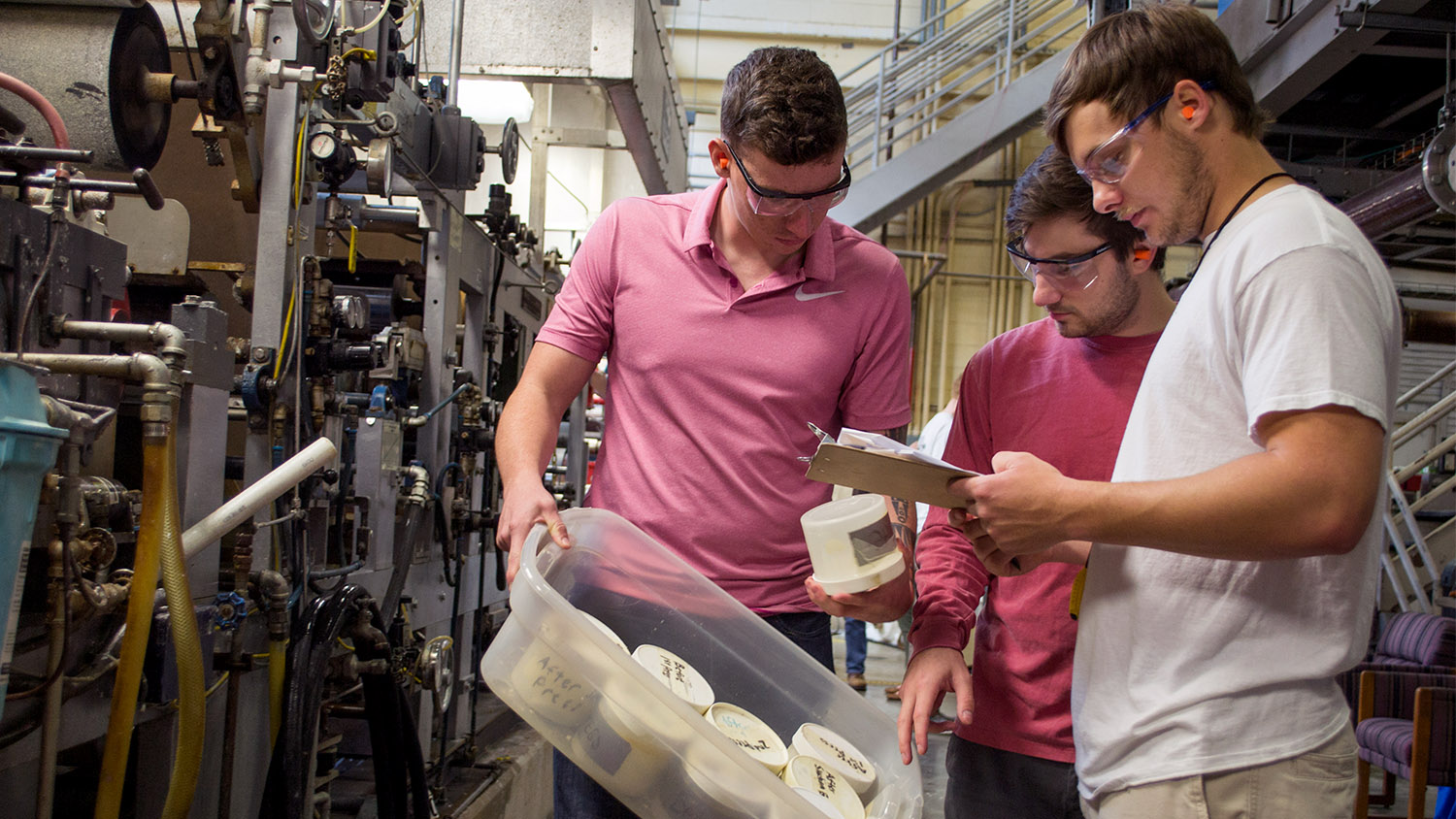

The mission of the Pulp and Paper Technical Services program is to support our allied industries with high quality, cost-effective services. From small-scale laboratory testing to pilot-scale production of large quantities of pulp or paper from a variety of sources, we are well-equipped for almost any technical challenge related to pulping and pride ourselves on a total customer focus.

Papermaking

We have great capabilities in papermaking at NC State. At bench scale, sheet moulds are available in a variety of sizes, with and without white water recycle. For pilot production of paper, the 12-inch “Wolfpack Baby” fourdrinier permits a cost-effective evaluation of a variety of furnishes and conditions.

Sheet Forming

Standard British Sheet Moulds

- Number available: 3

- Construction: 316 SS cast

Standard British Sheet Moulds with White Water Recycle

- Number available: 2

- Construction: stainless

- Sump pump can be enabled to recycle white water back into mould. Immersion heaters with temperature control.

Square Handsheet Mould

- Dimensions: 9.5 x 11.5 ” (24 x 29 cm)

Pilot Fourdrinier

First installed in 1957, the “Wolfpack Baby” was significantly upgraded in recent years. This small machine is quite flexible and permits the evaluation of a number of furnishes and process conditions in a short time period, which help keep costs low.

Features:

- deckle width 14-15″

- reel width 9-12″

- basis weight range 20-200 lb/3000 ft2 (33-325 g/m2)

- speed range 30-150 feet/mipilot fourdrinier (2)n (9-45 m/min)

- production rate 50-100 MD lb/hour

- atmospheric headbox

- wet end shake for good formation

- table rolls

- four vacuum flat boxes

- dandy roll

- full white water recirculation loop

- forward 1st press, felted

- reversing 2nd press, felted pilot fourdrinier (3)

- smoothing 3rd press, unfelted

- 1st dryer section with 8 steam-heated cylinders

- 2nd dryer section (after size press) with 5 steam-heated cylinders

- metering size press (go to page AK)

- calender stack with two hard, one soft nip

- Measurex 2002 scanner with basis weight and moisture control

- wet-end additives system with high-shear makedown tanks, continuous metering to multiple points on wet end

Paper Testing

NC State has a well-appointed testing laboratory capable of most routine and specialized testing.

Paper Testing

- Brightness, Opacity, color spectrum

- Tensile (regular and zero-span)

- Tear

- Burst

- Fold

- STFI Edge Compression

- Ring crush

- HST, Cobb

- Scott Bond

- Sheffield Smoothness, Parker Print Surface

- Gurley porosity

- Stiffness – Taber and vibrational

- Aging/Yellowing via controlled irradiation (Atlas Weatherometer)

- Image analysis (microscopic and scanner)