Meet Samaher Salem

Article originally written and posted to the Analytical Instrumentation Facility (AFI) website.

I am Samaher Salem, a final year doctoral student in the Department of Forest Biomaterials, and I am co-advised by Dr. Lokendra Pal and Dr. Lucian Lucia. I plan to continue to work in academia or research in either a university or government-associated laboratory. In my spare time, I play soccer, visit new places (especially the mountains), cook, and watch movies for fun.

What instrument(s) are you using for your research, and why do you like it/them?

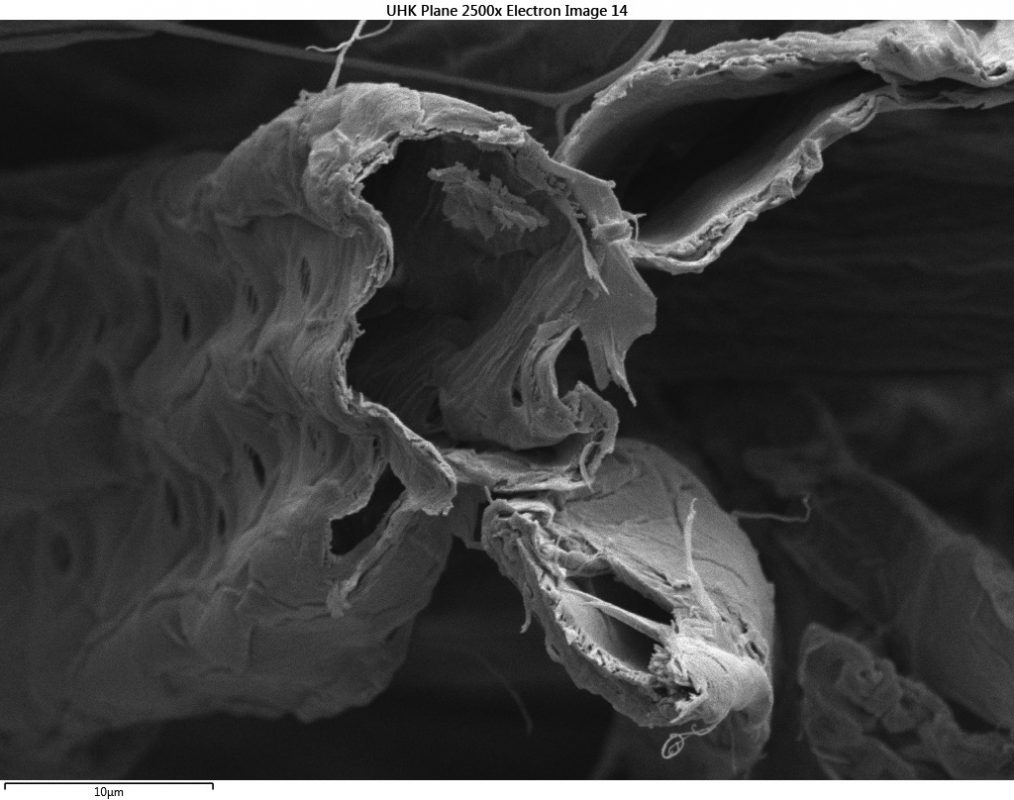

I have been using Hitachi S3200N variable pressure scanning electron microscope (VPSEM), FEI Verios 460L field-emission scanning electron microscope (FESEM), the Rigaku Smartlab X-ray diffractometer, and Time-of-Flight Secondary Ion Mass Spectrometer (TOF-SIMS) to analyze my samples. My research is focused on the surface modification of the lignocellulosic materials. The SEM images are beneficial to get an insight into the surface morphology of the modified materials. Imaging TOF SIMS provides information on the elemental and molecular change in the surface due to modifications. The XRD is a great technique to understand the crystallinity index of my samples, and it can be correlated to the degree of surface modification and, consequently, the performance.

What have you been researching, and how is it impacting the community?

The cellulose-water dynamic behavior is fundamental for many cellulose-based industrial applications such as paper, tissue paper and hygiene products, and bioplastics. As the world has been moving towards a sustainable, bio‐based, and circular economy due to social awareness and governmental regulations against single plastic use, cellulose nanofibrils have emerged as an important biomaterial as the application of bioplastics for food packaging has garnered significant attention in light of environmental pollution abatement from sustainability considerations. Chemical modifications of nanofibrils are necessary to improve barrier properties, like air, oxygen, water vapor, oil, and grease resistance, for packaging applications. However, water interaction with cellulose nanofibrils affects its chemical reactivity and has been found to regulate the degree of chemical modification and, ultimately, the final barrier properties.

My research focuses on understanding cellulose-water dynamics in macro-and nanoscale and design experiments to regulate water interaction with cellulose to produce modified cellulose nanofibrils with better physical and chemical properties preserving the integrity of the original morphology of CNF and maintaining native crystalline structure. We have successfully developed bioplastics from modified cellulose nanofibrils which have shown excellent barrier properties and biodegradability.

I hope this work would influence the use of renewable wood and non‐wood fibers as potential bioplastics for food packaging and help remediation of single-use plastics.

What have you learned from your experience at AIF?

AIF has helped me learn a lot about material characterization techniques and grow as a researcher. The SOP available for the instruments is very simplified as easy to follow. The experienced AIF staff have always helped me understand the theory and principles of the instruments, which have enabled me to do an in-depth analysis of my samples and comprehend the science to advance my research. The approach of AIF during the pandemic is commendable, and I really appreciate their effort to keep the reach of work moving by overcoming the limitations.

The best thing about AIF in 5 words or less?

Student-friendly, experienced, knowledgeable staff

Is there a staff member at AIF that has helped you?

I have reached out to Chuck, BB, Roberto, Fred, Elaine, Phillip, and Anna for testing my samples and other needs. I am really grateful to them for their kind and friendly support.

- Categories: