International Paper Software Donation Enhances Students’ Skills

New Software will better prepare our students.

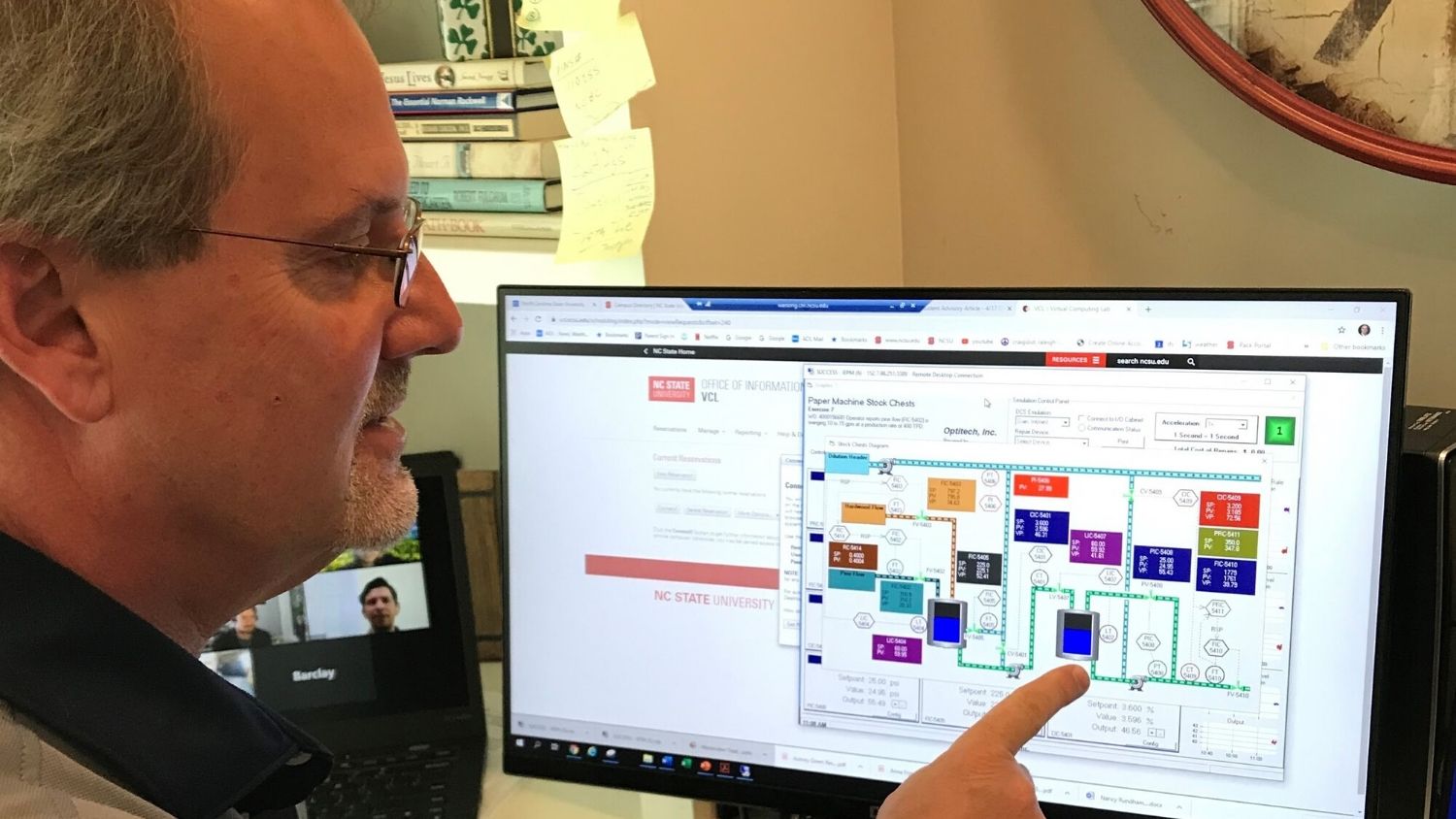

The Paper Science and Engineering program at NC State is considered the best of its kind in the nation, but the margin by which it holds that title might be increasing due to a generous donation made by International Paper. The donation enabled the PSE program to access the “Instrument and Electrical Precision Maintenance Controls Essentials Training Simulator Software”. The donation was made possible with the efforts of International Paper employees, Dale Stillwell, a 1981 graduate of NC State that holds a BS in Pulp & Paper Technology and Clark Hight, a 1986 graduate of NC State that holds BS degrees in Pulp & Paper Technology and Chemical Engineering along with Dr. Richard Venditti, a 1988 graduate of NC State that holds a BS in Pulp & Paper Technology and Chemical Engineering.

Loops, Sensors, Pumps and Values

The Software has multiple high-level simulation capabilities that together create a comprehensive ability to mimic many common processes in the Paper Industry, including the dynamic models of systems, such as control loops, sensors, pumps, and control valves. It is much like the Matrix, and while it might not be as flashy or have as many explosions as the film, it is just as revolutionary. One of the more important features is the ability for students to test solutions to process control issues while taking into account the cost to try out such ideas. “The student chooses one of the possible fixes and the program ‘charges’ the mill a bill for the cost. The student can then evaluate if the ‘fix’ worked; if the fix did not work then the student can then re-evaluate the diagnosis and try another fix, again the mill is billed…,” Venditti noted. Overall, this simulator provides students with the platform of a paper mill so that they become more familiar with process control while improving their problem-solving skills.

What’s the Benefit for Students

At the most basic level, the software provides a useful realistic experience for students. “The software can be used to teach students about process control,” Venditti states, “In particular, it provides students with real-life process control problems and allows the student to troubleshoot the process to identify the source of the problem.” However, this program doesn’t stop at providing the ability to diagnose a problem, it also teaches critical thinking and cost-benefit analysis. In this program, problem-solving skills are coupled with monetary constraints to mimic real life. In the Industry, resources are always limited, so the aim of the program is to help students balance creativity and capital. This is a trade-off that will greatly benefit them as they enter the workplace, as they will not only have hands-on experience with process control facts and theories, but also a touch of reality. Undoubtedly, the program will help NC State Students be better prepared and more efficient in their industry jobs on their very first day at work.

By guest Blogger Blaine Mercer