Dr. Lokendra Pal’s Paper Process Analysis

The roar of thousands of pounds of water draining…

The whirring of several large pumps…

The shouting of several dozen students…

All these sounds fill the department’s pilot plant every Monday afternoon in the Spring semester. The students mentioned are taking Dr. Lokendra Pal’s PSE 472 – Paper Process Analysis class. This course is the capstone course of the entire PSE curriculum and features a heavy hands-on lab component. For the students, every Monday presents a new opportunity to run the pilot paper machine.

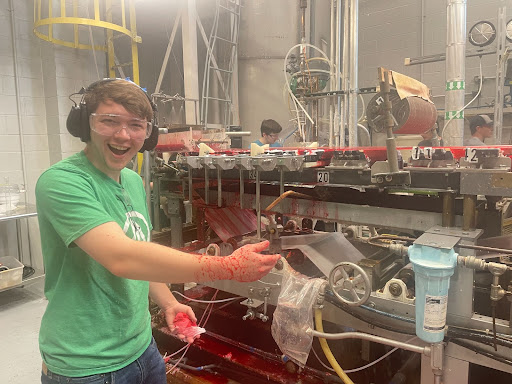

For fourth year student Matthew Klassa, this class has been on his agenda for years. “I’ve been waiting for this class and looking forward to it ever since I decided to come to State for PSE. I remember Dr. Byrd and the seniors always telling us about it, and I always thought to myself, I want to do that! That sounds fun! And now I get to do it, and it definitely is as fun as I thought it would be.” Matthew’s looking forward to the class is not unique. Many students remember hearing of this class and have been looking forward to it for years. Another fourth year student Jenny Nguyen told us what makes this experience so unique. “I really enjoyed being able to work on the WolfPack Baby machine because it connects what we learn in our classes to what we see in industry all on a smaller scale that we can really interact with more. There’s also something super satisfying about being able to hold up a roll of product and say ‘wow I really made this!’”

Dr. Pal has set up the course to give students a comprehensive understanding of the entire paper machine process. Students rotate through six lab duties, including stock prep, wet end operations, dry end operations, paper machine operations (designed to give students experience as “operators” for the run), coating preparation and testing, and paper (quality) testing. Each set of duties includes hands-on work while the machine is running, calculations based on data collected during the run, and a short presentation to the class based on those observations and data.

Throughout the six machine runs this semester, students have produced a survey of different grades including book paper, bond paper, watercolor paper, SBS board, medium weight coated paper, and recycled linerboard. Fourth year student Heaven Davis said her favorite grade was recycled liner. She explained, “I have previously worked in a linerboard mill, so to see it on a smaller scale and really be able to understand the different machine changes required for liner rather than a different grade was really unique!”

Jesse Price, another fourth year in the program, provided us some insight on what truly makes this class stand out. “Running the Wolfpack Baby paper machine provides a surreal and entirely different lab experience than any other in my time at NC State. In typical labs, we are given a specific set of procedures that students follow in order to generate the numbers they need to finish the lab work. We do not deviate from those procedures and as long as we follow them, the exact numerical results we gather do not matter – there is only pressure to get numbers, and errors are generally forgiven. I found that those labs do not require much critical thinking, as all the thought has already been put into the procedures by someone else. Dr. Pal’s paper machine runs provided a whole new experience for those students who were used to the typical lab structure. Our purpose while running the machine was to first and foremost make good paper in a safe way – collecting data was only really a means to analyze, document, and improve our runs. Running the machine was an involved and evolving process, especially when there is difficulty in getting the sheet on the reel. If we cannot do that, Dr. Pal would tell students that are waiting to be able to take data to go record different unplanned data to help in troubleshooting. He would bring issues to groups such as, ‘Our basis weight is five pounds lighter than we need – here is the relation between valve opening and basis weight– go calculate how much of a change we need in the valve to reach the correct basis weight,’ and once they brought back the answer, he would make the change they suggested. The success of the run depends on those students’ calculations in the moment. This shift in labs from following procedures to adapting and improvising in order to meet a collective goal serves to help transition us from procedure following to problem solving that we’ll need in the future workforce. Synthesizing all of our learned knowledge to run the Wolfpack Baby is really a true test of our ability to adapt and apply what we have learned in the workplace. It signals the shift from following procedures to improvising around change. These are the things that take our education from academic to applied and practical.”

As exemplified by many students, PSE 472 is both a unique class and a unique experience. It is one of many things that sets apart the Paper Science & Engineering program at NC State from any other program or school.

Author: Matthew Klassa, PSE senior

- Categories: