Hodges Laboratory: NC State’s Hidden Gem

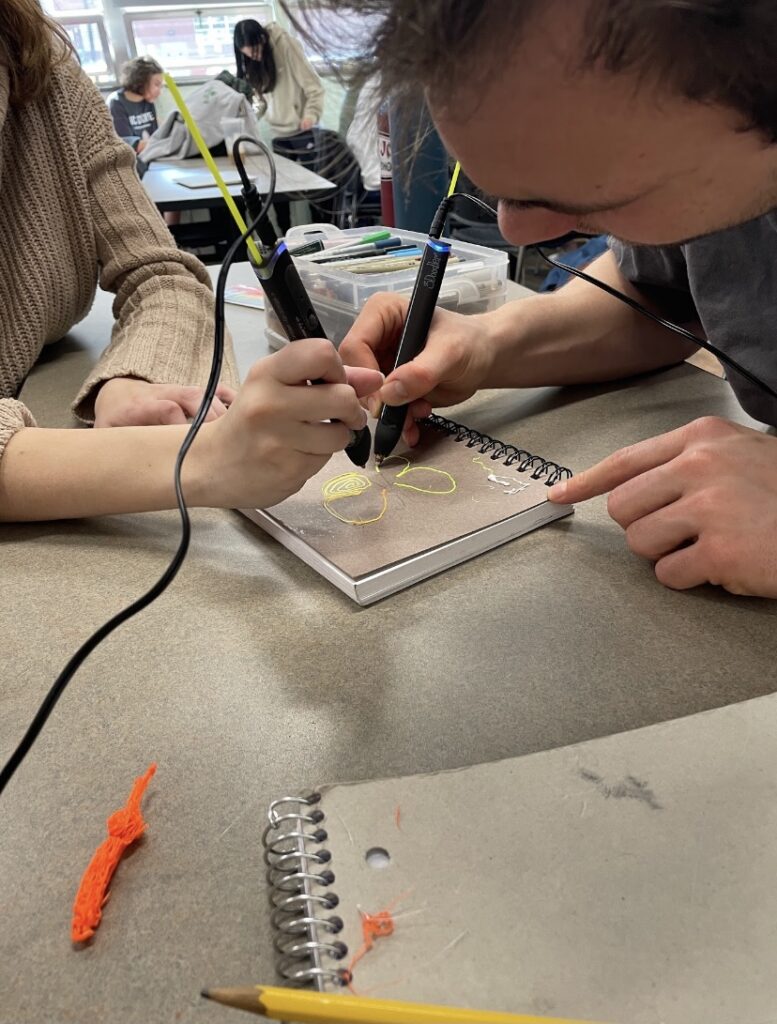

Sustainable Materials and Technology is an engineering-adjacent program at NC State that offers a variety of enticing attributes such as smaller class sizes, meaningful professor-student relationships, and a 100% job placement 6 months post graduation. However, one of its most valuable and unique assets often remains in the shadows. Hodges Wood Products Laboratory is the heart of the Sustainable Materials and Technology (SMT) program where faculty and students alike are able to conduct groundbreaking research from the comfort of their own space. Unlike other labs on campus, Hodges is strictly dedicated to the SMT program as well as Forest Biomaterials graduate students. A variety of SMT classes are held here in order to expose students to various job-related skills and technology through hands-on experiences. Students may be frequently spotted using the facility’s laminate testing lab, wood product machinery, butane burners, virtual reality headsets, and 3D-printers in both classes and lab sections.

Hodges initially opened its doors in 1960 with the original intent to provide faculty and students with the ability to gain real world experience as well as provide research opportunities to its inhabitants. Initially constructed solely as a wood products facility, Hodges has since broadened its horizons to allow for a larger breadth of sustainable materials. This now enhanced resume includes researching and working with all types of biomaterials (organic material derived from the earth) and biomasses (organic material that can be used for fuel), rather than solely wood. The lab is equipped with cutting-edge equipment and facilities that allow faculty and students to conduct biomass research including sustainable material chemistry, processing, and engineering. A recent example of this research comes from the work of Sunkyu Park, Professor & University Faculty Scholar in the Department of Forest Materials. Sunkyu Park is currently using Hodges Laboratories to conduct research on creating sustainable aviation fuel and graphite. Using a state-of-the-art pyrolysis reactor at the facility, Dr. Park and his team are creating graphite from biomass, where they hope to transform this byproduct into batteries that may replace those in phones and other electronic devices. This research, which has the potential to have a substantial effect on creating clean and practical energy sources in the future, was recently granted 2.25 million dollars from the Department of Energy to continue its efforts to develop products for a more sustainable future.

Isaac Dailey, a senior in the Sustainable Materials and Technology undergraduate program was questioned about his work in Hodges with Dr. Park and the benefits of this facility. “I am currently working for Dr. Park to produce graphite for lithium batteries, using biomass to produce the graphite. I have been able to use the tube furnace in Hodges to produce the graphite before taking it to the pulp and paper labs to weigh it and compare it to other synthetic graphites. After this, we take it to NC State’s Analytical Instrumentation Facility staff to run various tests on it. Working with Dr. Park in Hodges has allowed me to branch out into materials that I am not too familiar with. I have been able to gain skills working with equipment that I may not have been exposed to had I not worked with him in this facility this year. Like any research project, it has allowed me to gain new technical skills, make new connections and learn something new outside of the classroom which is always a valuable experience.”

Hodges Wood Products Lab also houses other research studies devoted to the advancement of wood and biomass products. Researchers at the lab continuously work on developing new composites that aid in combining sustainable materials with other substances such as plastics or metals. These new materials have a range of applications, from construction materials to furniture and flooring. When asked about the most notable addition to Hodges, JT Chappel, a junior Sustainable Materials and Technology student responded: “While I haven’t been here for too long, I definitely believe that one of the most notable changes in Hodges is the introduction of the Sustainable Design Lab (Fabrication and Ideation Lab). This space provides students and faculty with the creative liberty to design and even construct sustainable products using relatively new and unique technologies.”

This facility houses a fully functional kiln and laminate testing facility as well. Various companies send freshly cut wood to Hodges kilns to be dried for their industrial purposes and needs. Flooring companies whose products can be found in Lowe’s or Home Depot, will send samples of their products in order for students to test how it holds up against a variety of elements such as UV radiation, drops, daily wear and tear, and scratches. Once complete, students will send findings back to the company for improvement of their product. “Hodges is a neat building that contains decades worth of history and equipment in addition to new, state-of-the-art technology that enhances students’ learning experiences,” says Melzer Morgan IV, a current senior in the Sustainable Materials and Technology program. “I have spent a great deal of time over the last four years in Hodges in classes and as an undergraduate laboratory assistant for the Testing Services Department. The building provides a plethora of resources that enhance students’ educational experience and allows us to engage in hands-on projects and research.”

In addition to its research activities, Hodges is home to the vast majority of classes in the Sustainable Materials and Technology major and minor programs, making it a secondary residence for many of the faculty as well as students. These classes allow students to take advantage of hands-on learning experiences relevant to the workforce. In addition to the previously mentioned amenities of Hodges, it also houses multiple 3D printing labs that include a metal 3D printer, an Oculus design room where students make use of CAD software, a mechanical testing lab, and a Fabrication and Ideation Lab, all of which are incorporated into the Sustainable Materials and Technology curriculum. Best of all, it has a student lounge where students can relax by playing ping pong or foosball.

While interviewing two current students, both had similar feelings towards the staple building of the Sustainable Materials and Technology program. SMT student Izzy Jackson: “Hodges has facilitated a very hands-on way of learning as much of the building is a lab setting! Seeing how the information learned in many of the classes is applicable in the lab makes Hodges an exciting place to figure out your path within the sustainable world!” Additionally, JT Chappell had similar thoughts on the facility: “Hodges provides me with a space to utilize the skills and knowledge that I have developed in the classroom in a way that I feel contributes to society as a whole. It also provides me with the opportunity to interact with various members of the faculty via research and/or laboratory experiences, which facilitates the development of new skills that can help make me a valuable asset in a wide range of fields.” This is more than just another run-of-the-mill facility for some students; it’s amenities allow them to separate themselves from the competition of other universities.

Students are not the only ones that believe Hodges is a one of a kind facility; the faculty believe this as well. When asked what makes Hodges unique and special, Daniel Saloni, a professor in Sustainable Materials and Technology had this to say:

“I came to the U.S. twenty-two years ago, and Hodges became my working place. Yet through the years, it has also become my space to create, relax, and stress. I started working as a visiting scientist in one of the main areas of research in Hodges: Abrasive Machining. There were several sanders by then: a wide belt sander, stroke sander, edge sanders, disk sanders and others. Thus, I had every single machine to perform my work. After completing my visiting work, I was offered a scholarship to start my graduate studies and continue working on abrasive machining. We developed and adapted new machines creating state-of-the-art abrasive machining research areas with international recognition thanks to the equipment and a great team. Throughout the years, I have seen the evolution of Hodges, with new innovative research areas, new researchers, and student traffic. Yet it always maintains the same welcoming space to meet, perform your work, provide extension training, and many others. Thus, many students, faculty, staff, and visitors have taken advantage of the several opportunities that Hodges hosts.”

Thanks to Hodges, or as Dr. Saloni used to call it, the “Pizza Oven”, the Sustainable Materials and Technology program is able draw on the expertise of faculty members from a variety of departments, including wood and paper science, textile engineering, materials science and engineering, and chemical and biomolecular engineering. This interdisciplinary approach, coupled with our long standing and experienced professors, allows students to gain a broad understanding of sustainable materials and technologies to develop the skills needed to tackle complex problems.

Hodges Wood Products Lab truly is the hidden gem of NC State’s campus with a rich history. It is a vital part of our University’s commitment to research and education on sustainable and innovative bio-products. Its world-class facilities and expertise bolster NC State’s ability to be a renowned and respected leader in the field. And its work contributes to the greater good, in the ability to develop a more sustainable products industry nationwide.

By: Abby Norris, Student Services Coordinator